The mechanical design of the equipment considers the loads generated in operation.

After defects being revealed in field tests and feedback being given during the transitional heating, cooling and regeneration stages, the design is correspondingly enhanced.

The verticality and straightness of the outer basket are measured by laser, and the roundness is controlled within a certain error range.

Application: Gas treatment, Platforming, reforming, CCR, ammonia converter, styrene.

Design based on your application

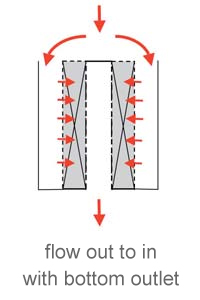

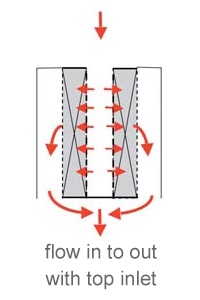

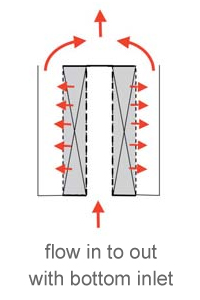

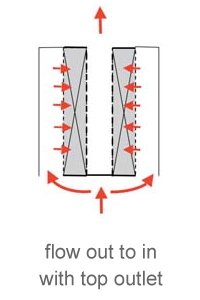

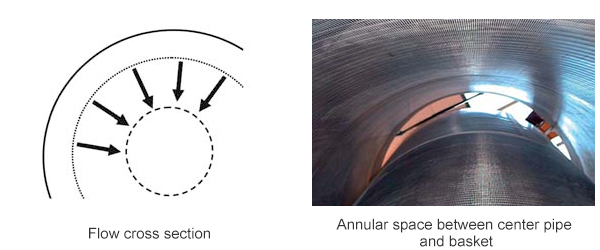

The cover deck closes the gap between the internal screen component and the scallop. The flow direction could be outward or inward.

The outer basket is a single-piece component installed across the entire vessel cross-section. It stands independently on a support ring fixed to the vessel shell.

Being self-standing, the outer basket creates a greater distance from the inner vessel surface, allowing for higher flow capacity. The annular gap remains consistent regardless of the flow direction. Since it is detached from the vessel shell, it bears the full mechanical stress from the catalyst bed while avoiding compression from the stress transmitted by the vessel shell.

Design Parameters

Process parameters:

The gas flow and pressure drop through the catalyst are key process factors used to determine the outer basket's inner diameter relative to the vessel shell, its length, and the distribution system, including perforation percentage, if applicable.

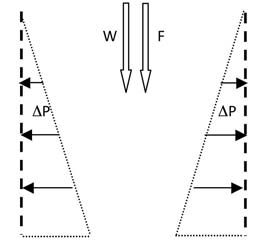

Mechanical parameters:

Mechanical considerations such as catalyst weight (W), axial load (F), radial load (ΔP), design temperature, operating cycles, and start-up/shut-down conditions are required to define the necessary reinforcement.