Wiped Film Evaporator has the advantages of high heat transfer efficiency, short residence time, and operation under vacuum conditions, so it has been widely used in many industries. In the chemical industry, it is mainly used in the production of fine chemical products and petrochemical industry; In the pharmaceutical industry, it is mainly used in drug concentration and purification, and the treatment of traditional Chinese medicine extracts.

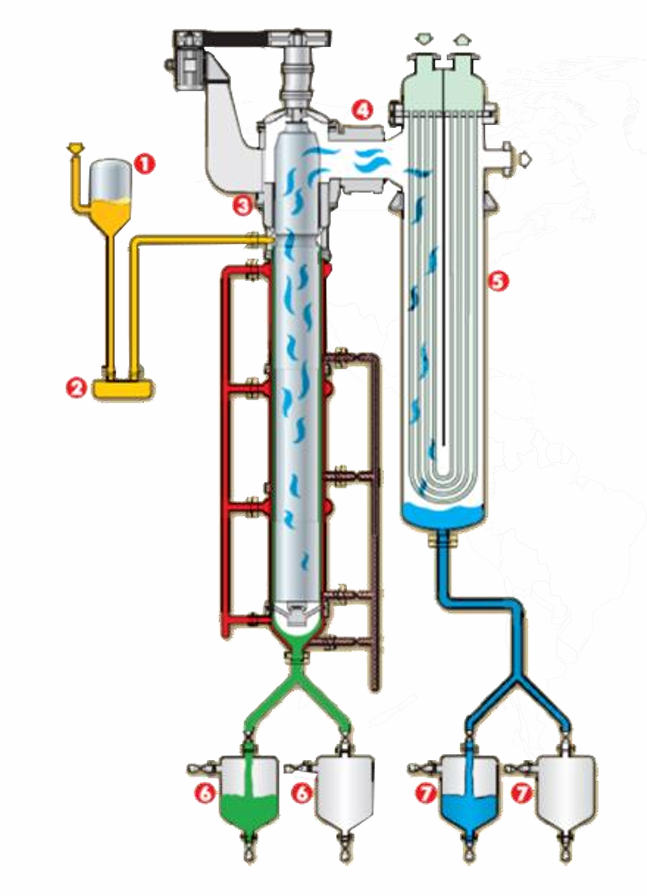

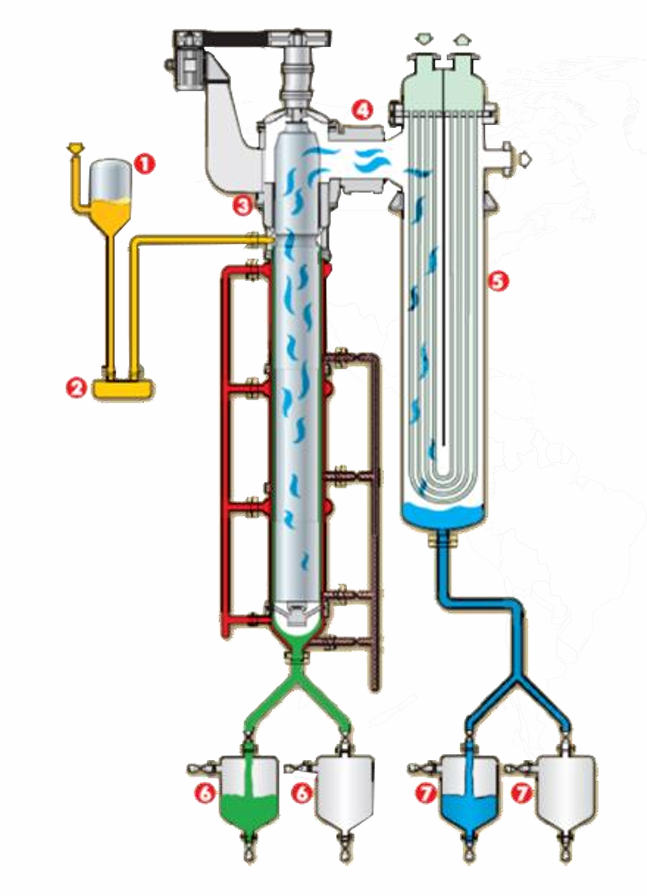

Structure:

1. Feed tank

2. Feed preheater

3. Wiped Film Evaporator

4. Gaseous phase substance

5. Condenser

6. Heavy phase substance

7. Light phase substance

Features:

1. Wide adaptability: materials with high viscosity, heat sensitivity, easy to crystallize and scale;

2. High efficiency, large capacity, large evaporation per unit area, evaporation of water and organic solvents and other solutions 80~300Kg/h·m²;

3. The residence time of the material on the evaporation surface is short, about 10 seconds, and it is not easy to coke and scale;

4. It can achieve low-temperature evaporation under high vacuum conditions and save heat source;

5. It can be suitable for automatic continuous production, with large operation flexibility, simple structure, easy maintenance, and automatic control;

6. Change the shape of the scraper (the groove inclination angle on the outside of the scraper) to adjust the time of the material staying in the evaporator to meet the needs of evaporation of materials of different viscosities.

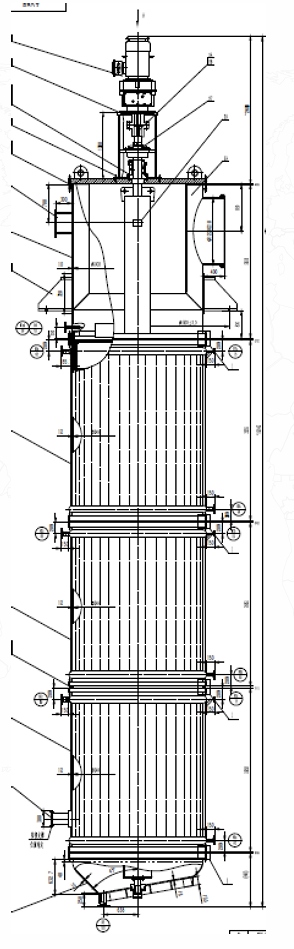

Main configurations:

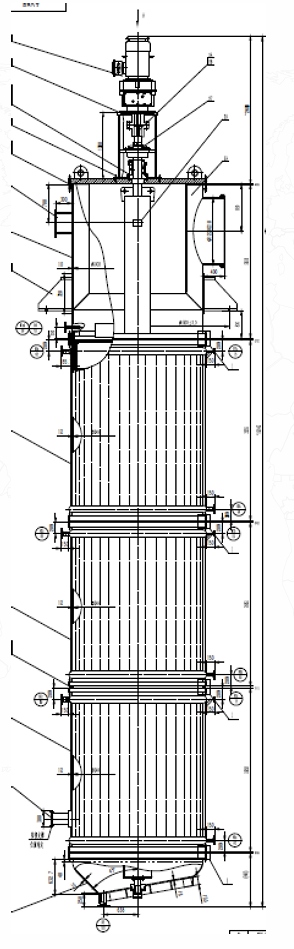

1. Container housings with jacketed or half-tube heating;

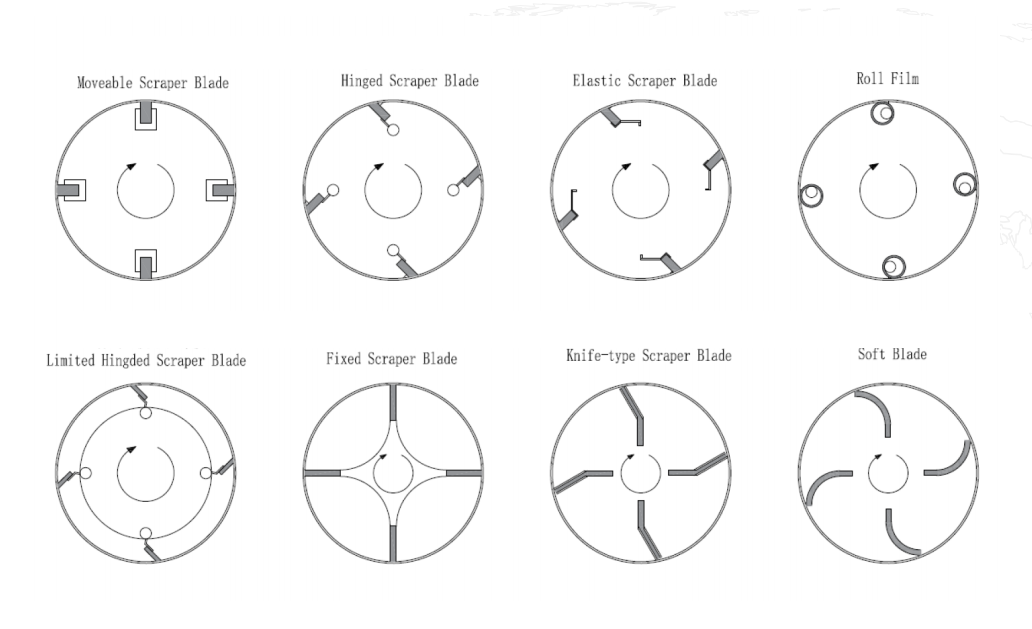

2. The rotor can be configured with different scraper forms: movable scraper, fixed scraper, hinged scraper, etc.;

3. The distributor can be evenly distributed with materials;

4. The gas-liquid separator can be entrained by means of mist;

5. Bottom seal head with external or built-in bearing support rotor.

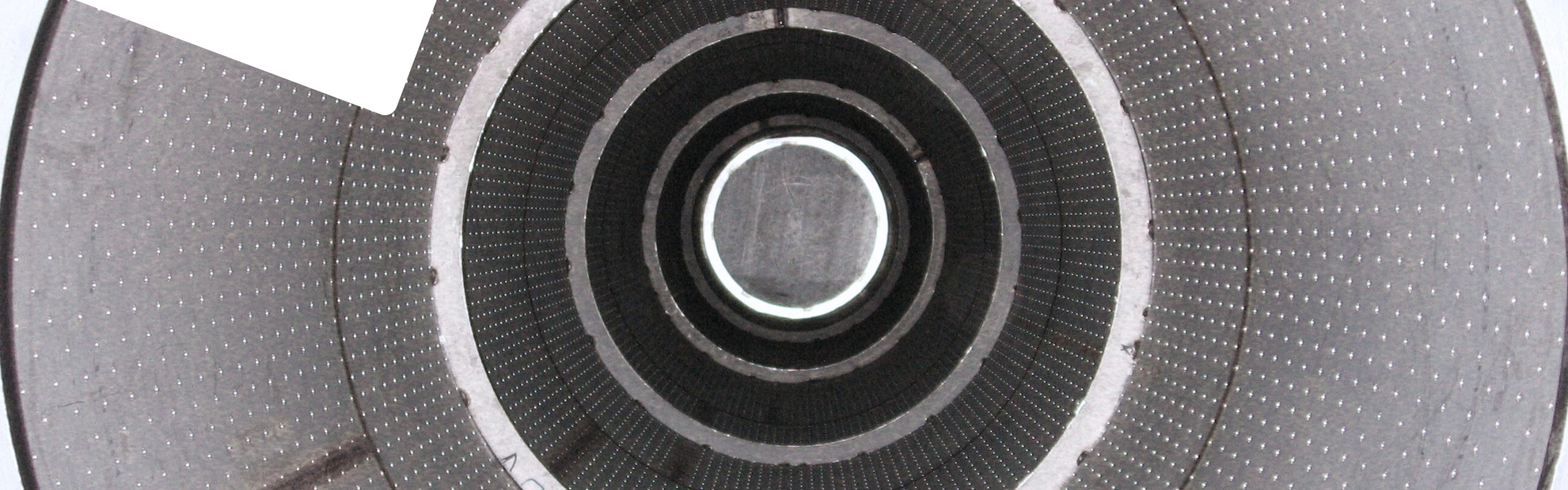

Rotor features:

1. Different rotors are available for different substances;

2. Through the selection of different rotor forms, the residence time of the material and the thickness of the lamination can be controlled to optimize the evaporation efficiency;

3. According to the selection of the rotor and the perfect match with the comprehensive performance of evaporation, in order to achieve the perfect combination of cost and efficiency;

4. According to the choice of rotor, the heat source can be saved under the condition of improving the evaporation efficiency;

5. Easy maintenance.