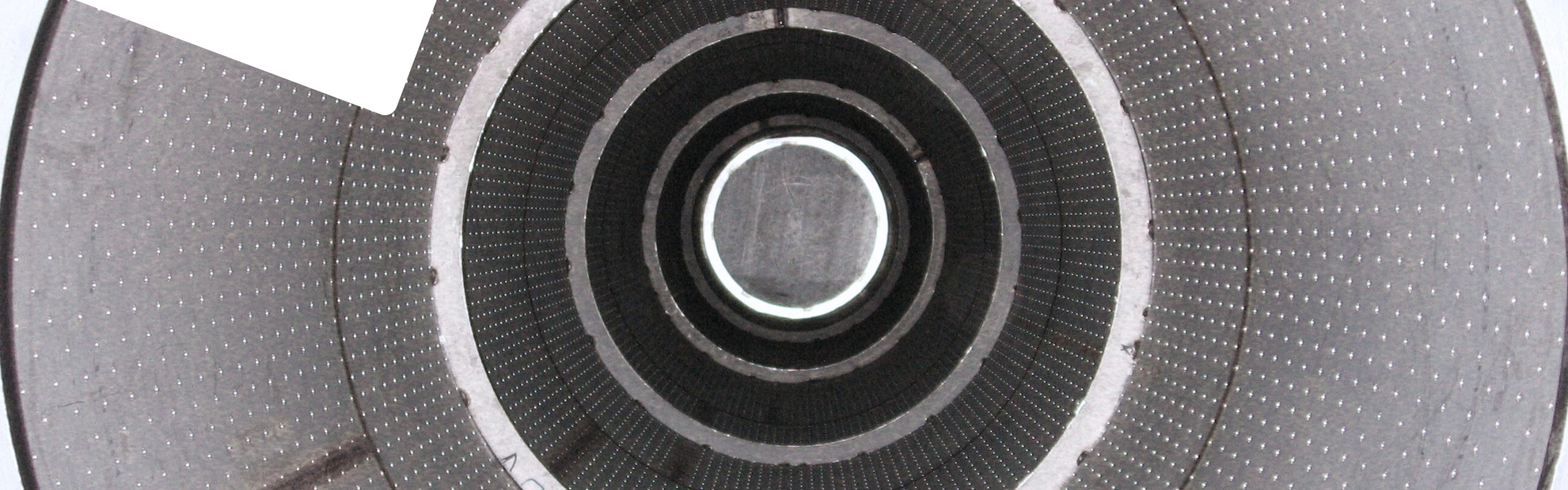

Internals for Radial Flow Reactors

A radial reactor is a type of reactor where the gas flow direction is perpendicular to the axial direction of the equipment. It is commonly used for gas-solid catalytic reactions, as well as for non-catalytic reactions. As the reaction gas flows through the particle bed in a radial reactor, the large cross-sectional flow area, low flow velocity, and short flow path contribute to its key characteristic: a minimal pressure drop.

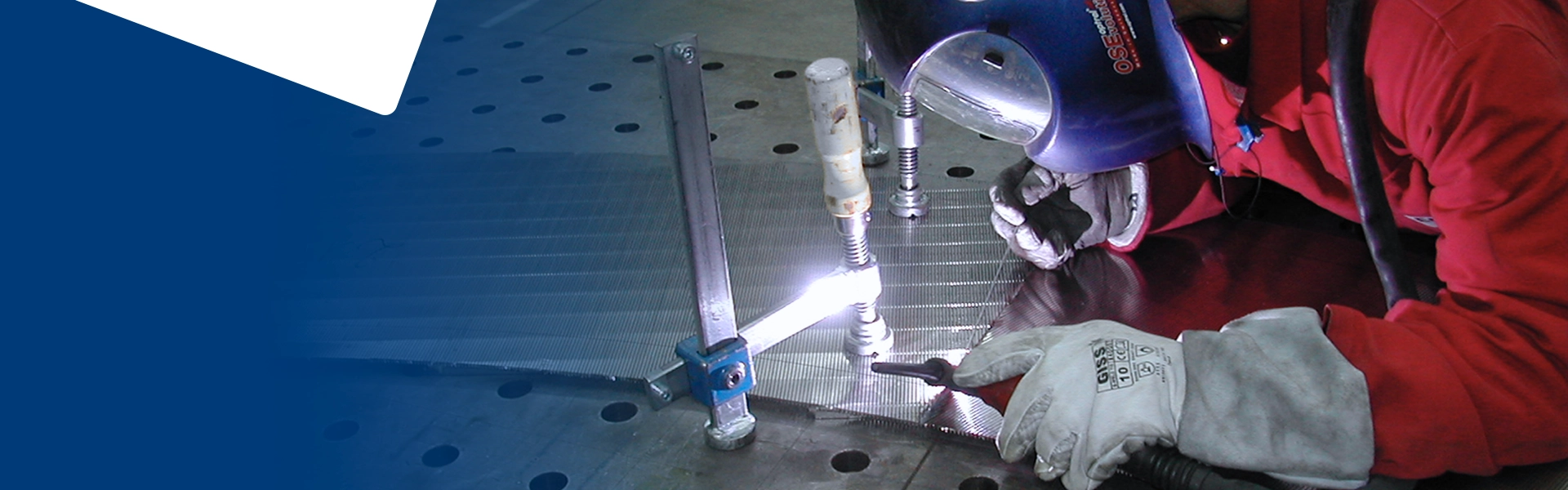

We manufacture critical components such as center pipes, scallops, and outer baskets for radial flow reactor vessels. We strictly adhere to ASME code requirements for carbon content in materials designed for high-temperature operation, ensuring the reliable and efficient performance of radial flow reactors.

We manufacture critical components such as center pipes, scallops, and outer baskets for radial flow reactor vessels. We strictly adhere to ASME code requirements for carbon content in materials designed for high-temperature operation, ensuring the reliable and efficient performance of radial flow reactors.